At Thales Avionics, I was the Industrial Designer on the Inflight Entertainment and Connectivity Group’s Mechanical Engineering Team. My internship immersed me in the lifecycle of development and helped me understand how ideas become an actual product.

From my studies as an industrial design student, I understood how product concepts are researched and designs prototyped. However, I did not have a full understanding of how the final design was put into production. I had the opportunity to learn about and participate in each stage in the development of several products, including: sourcing raw materials, manufacturing, prototyping, product testing, reverse engineering, and revising documents.

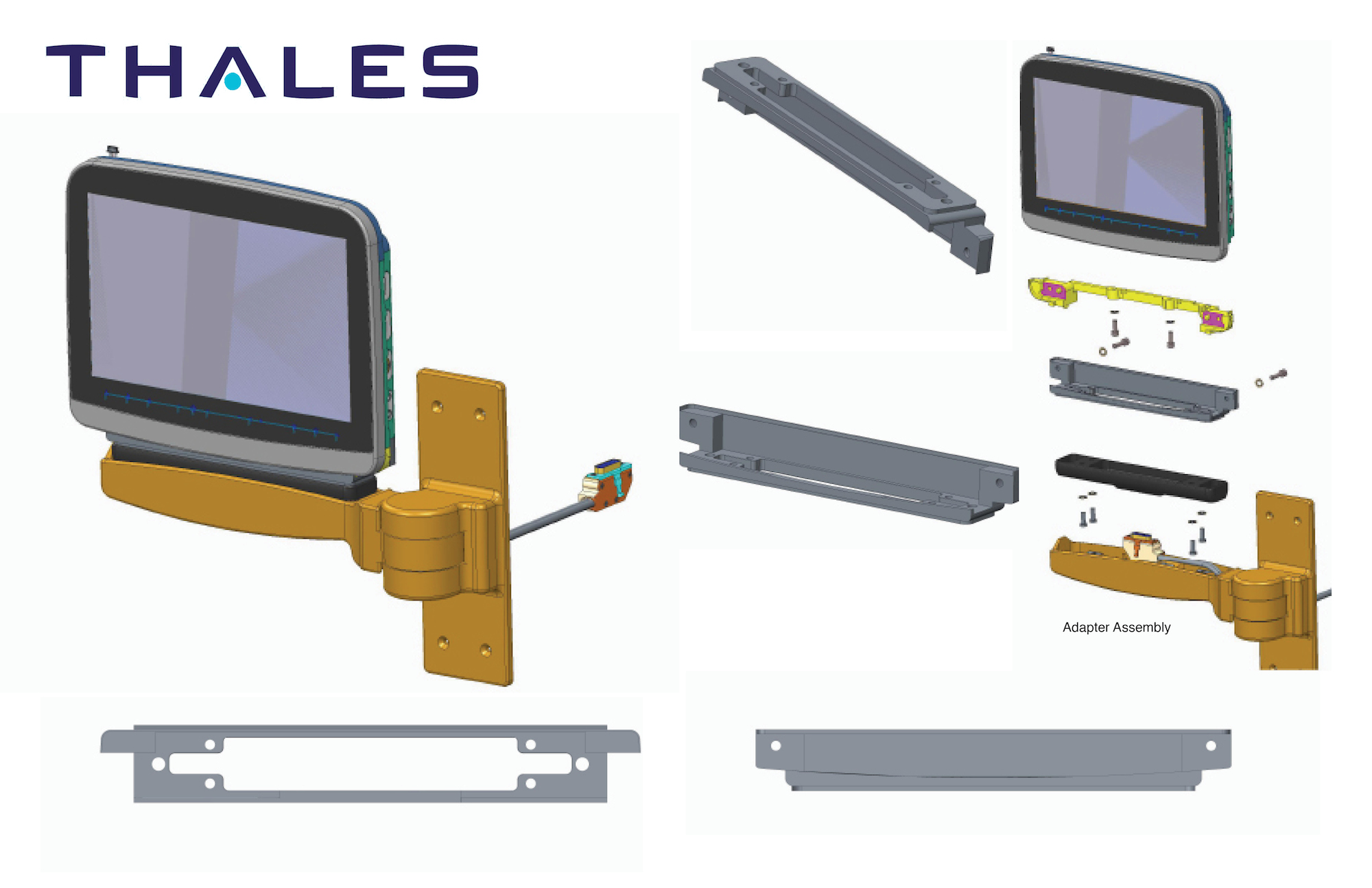

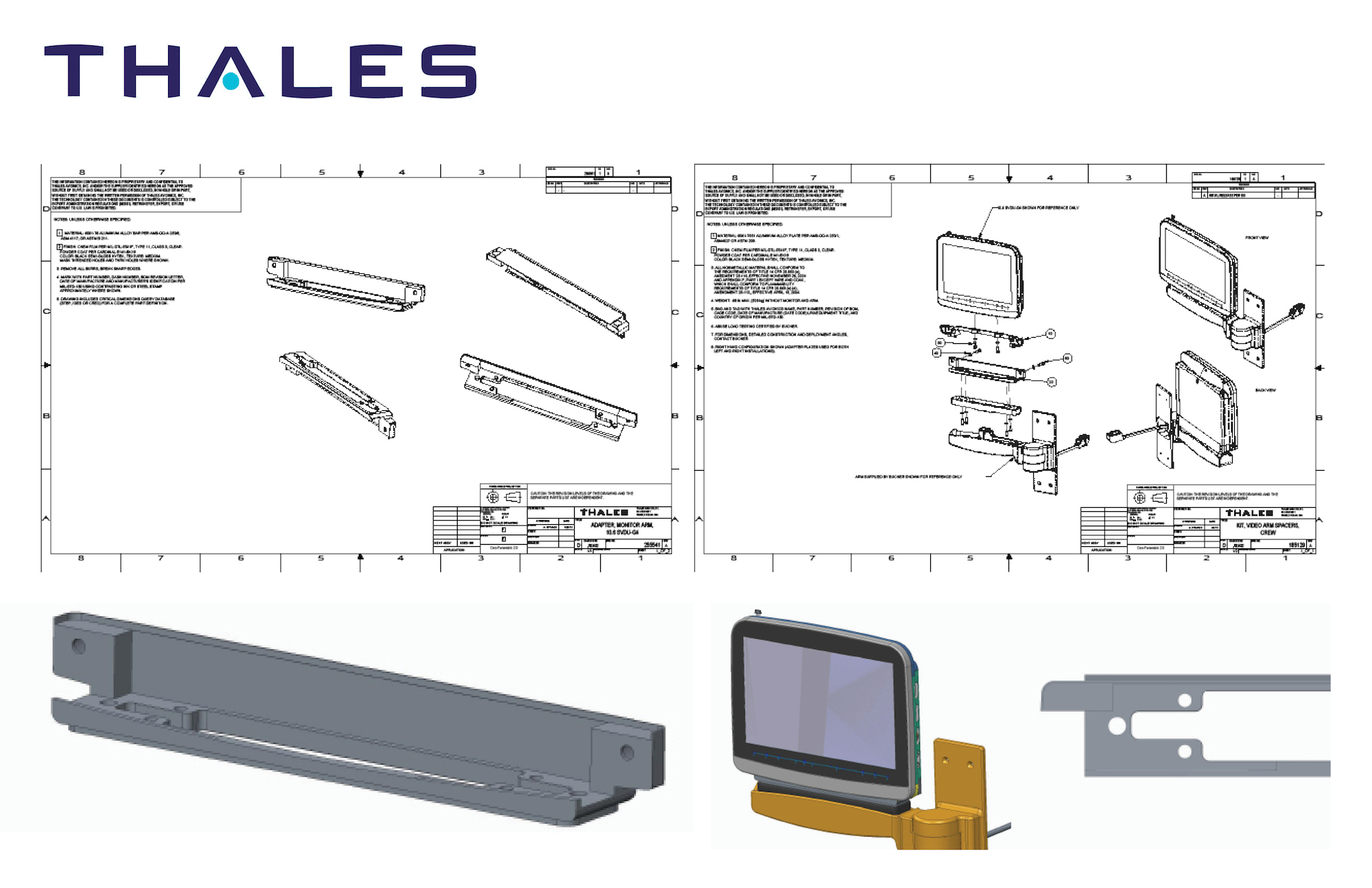

I also designed a new adaptor plate for a Boeing commercial aircraft that integrated two separate components and delivered the final prototype with production specifications. The adaptor is currently being manufactured.

The Adaptor Plate That I Designed:

![]()

![]()

From my studies as an industrial design student, I understood how product concepts are researched and designs prototyped. However, I did not have a full understanding of how the final design was put into production. I had the opportunity to learn about and participate in each stage in the development of several products, including: sourcing raw materials, manufacturing, prototyping, product testing, reverse engineering, and revising documents.

I also designed a new adaptor plate for a Boeing commercial aircraft that integrated two separate components and delivered the final prototype with production specifications. The adaptor is currently being manufactured.

The Adaptor Plate That I Designed: